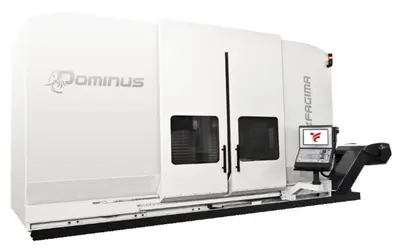

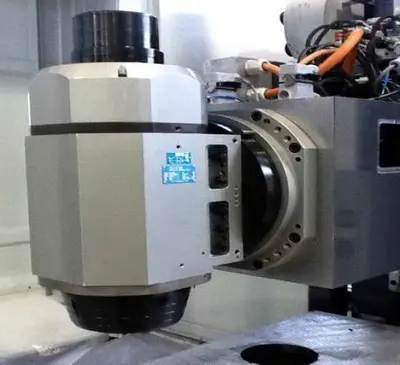

The FAGIMA DOMINUS BIG 4AX 2200 is a powerful moving column 5-axis machining center designed for high-precision and heavy-duty applications. Compared to the standard Dominus, this model is engineered for larger workpieces and special machining operations. With its double-column vertical axis reaching up to 1500 mm, it ensures excellent stability, accuracy, and performance.

Built with a rigid monolithic steel base and ribbed steel column, the Dominus Big guarantees structural strength and high machining precision. Its longitudinal travel with a central fixed table enhances stability, while Heidenhain absolute optical scales provide accurate axis measurement. The spindle design allows machining of a wide range of materials, from light alloys to very hard steel alloys, making it suitable for aerospace, maritime, energy, and general mechanical sectors.

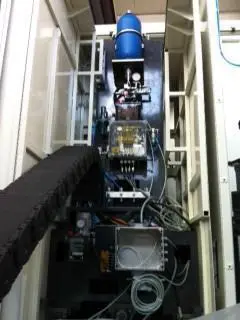

An efficient chip removal and cooling system keeps the working area clean, while servo drives combined with ball screws and roller guides ensure high feed speeds and positioning accuracy. The user-friendly design also allows easy access to the working area, making it a versatile and reliable solution for demanding industries.

Key Features:

• Large working capacity with vertical axis up to 1500 mm

• High stability and precision with rigid steel base and column

• Heidenhain absolute optical scales for accurate axis control

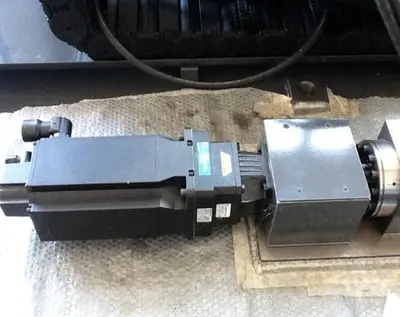

• High-performance spindle for light to hard alloy machining

• Servo drives with ball screws and roller guides for fast and precise movement

• Effective chip removal and cooling system

• Easy access to the working area for operator convenience

We use cookies to improve your experience. Privacy Policy.