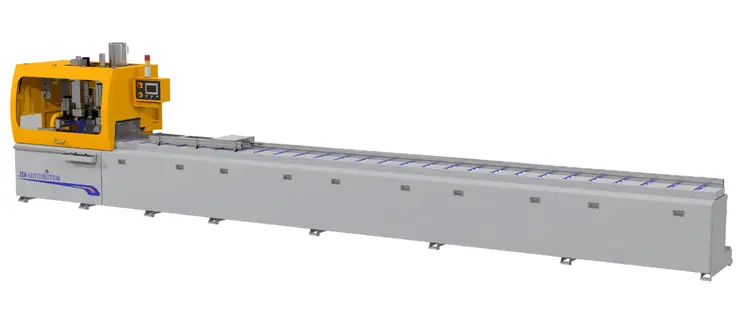

Multi-Function CNC Machine for Small Part Processing | High Speed | High Precision

The JIH-AUTO18DTS is a fully automatic drilling, tapping, and sawing machine engineered for small part production where precision and productivity matter. Combining three functions—drilling, tapping, and sawing—into a single platform, this multi-functional CNC solution streamlines manufacturing processes with high efficiency and accuracy.

Designed for flexibility, users can select any of the three operations independently or run all simultaneously, boosting output while saving time and space. The automatic feed stroke ranges from 2.5M to 6.5M, allowing for parallel cutting of multiple parts within the processing range. The system is powered by a servo-driven belt system, supported by a user-friendly 9.7" NC touch screen with PLC control for simple, intuitive operation.

Whether you're in aluminum fabrication, metalworking, or industrial component manufacturing, the JIH-AUTO18DTS offers outstanding cutting accuracy, automated positioning, and stable high-speed operation, making it an ideal addition to any high-volume production line.

Key Features:

• 3-in-1 functionality: Automatic drilling, tapping, and sawing in one compact machine

• Servo motor positioning for high-precision drilling and tapping

• Auto feed stroke up to 6,500mm (optional 2,500~5,500mm available)

• Parallel cutting capabilities for multiple pieces simultaneously

• Touchscreen PLC control with simple interface (9.7”)

• Built for high efficiency, small part machining, and repeatable accuracy

CE COVER

AUTO3000 - 7.2M ACTUALLY MEASURE 6.5 M* 1SET

18" SAWBLADE 1PC WITHOUT FIXTURE

X/Y/Z AXIS BY SERVO

2 DRILL

2 TAPPING

PROCESS 1 MATERIAL WITH DRILLING, 2 HOLE AND TAPPING TOGETHER

2 DRILLING WORK WITH SAME PITCH MATERIAL (IF NOT THE SAME, CAN USE 1 DRILLING)

We use cookies to improve your experience. Privacy Policy.