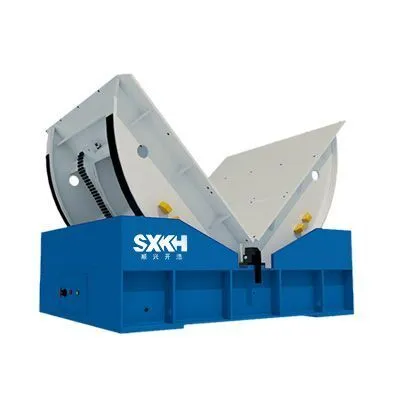

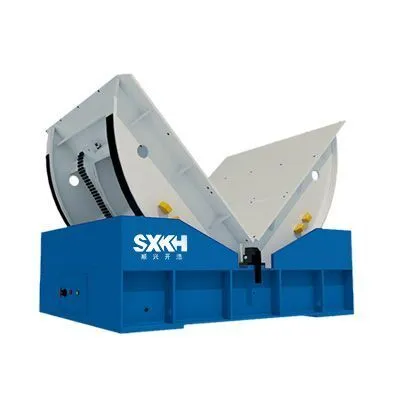

SXKH Mechanical Mold Flipper – Safe, Efficient, and Space-Saving Mold Handling

The SXKH Mechanical Mold Flipper is designed to make the turning and flipping of large molds and dies safer, faster, and more efficient. When maintaining molds used in horizontal injection molding or die casting machines, flipping them manually can be risky, time-consuming, and labor-intensive. The SXKH Mold Flipper provides a reliable, motor-driven solution for 90-degree and 180-degree mold flipping, ensuring smooth and effortless handling of heavy molds.

Powered by an electrical motor, the SXKH Mold Flipper operates with minimal maintenance and low energy consumption. Its compact design requires less space, making it ideal for factories with limited floor area. The double-rail and bush roller chain system ensures stable and controlled movement, while the travel switch and rotation bracket securely limit the motion at the 90-degree position, preventing over-rotation. Equipped with an electric cabinet and a moveable operation panel, the system offers user-friendly controls for a seamless and efficient mold-flipping process.

With over 10 years of expertise in mold-handling solutions, SXKH delivers a proven, high-performance mold flipper that enhances safety, productivity, and ease of operation.

Key Features:

• Electrical Motor Driven – Ensures fast, smooth, and maintenance-free operation

• 90-Degree Mold Flipping – Safe and efficient for horizontal mold maintenance

• Double Rails & Bush Roller Chain – Provides stable and controlled mold rotation

• Travel Switch & Rotation Bracket – Limits movement at the 90-degree position for added safety

• Electric Cabinet & Moveable Operation Panel – Simplifies control and enhances ease of use

• Space-Saving Design – Compact and efficient, ideal for factories with limited space

We use cookies to improve your experience. Privacy Policy.