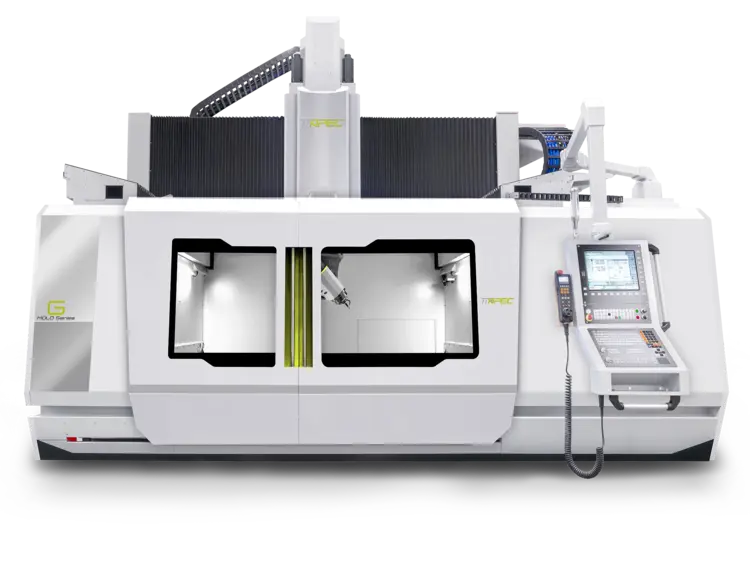

Experience unmatched precision and efficiency with the APEC G3020 5-Axis Gantry Vertical Milling Center — a next-generation solution for complex and high-performance machining. Engineered for aerospace, automotive, and mold-making industries, the G3020 delivers superior accuracy, dynamic performance, and thermal stability, handling diverse materials and intricate geometries with ease.

Built on a rigid U-shaped structure, the APEC G3020 combines linear motor-driven X/Y axes and a hollow water-cooled Z-axis to ensure exceptional positioning accuracy and maximum stability even during heavy-duty cutting operations. Its compact two-axis milling head delivers high torque and smooth contouring, making it ideal for aerospace machining, automotive components, precision mold & die making and complex 5-axis parts.

Key Features:

• Large Travel Range: 3,000 mm (X) × 2,000 mm (Y) × 1,200 mm (Z) — ideal for machining large workpieces.

• Precision 2-Axis Milling Head: ±115° (B-axis) and ±360° (C-axis) swivel rotation, with 4,000 Nm clamping torque.

• Thermal Stability: Water-cooled Z-axis and cooler-equipped linear motors for consistent precision machining.

• Accuracy: Positioning precision of up to ±0.010 mm and repeatability of ±0.008 mm per VDI/ DGQ 3441 standard.

• Integrated workpiece touch probe and tool measurement system for automatic calibration.

• Efficient Chip Management: Standard chip conveyor and water tank for cleaner operation.

• Enhanced Reliability: Germany braking system for linear motors, counterbalance system, and air-conditioning for electrical cabinet.

Why Choose the APEC G Series?

Combining high-speed cutting, robust construction, and intelligent thermal management, the APEC G3020 helps you elevate your 5-axis CNC machining capabilities. Whether it's aluminum aerospace structures, complex automotive parts, or heavy-duty molds, this machine guarantees precision, versatility, and productivity.

HEIDENHAIN TNC640 WITH HR520 MPG

AGA MONO TYPE 2-AXIS MILLING HEAD

EXTENDED Z-AXIS TRAVEL TO 1,200 MM

15,000 RPM BUILT-IN SPINDLE, SPINDLE MOTOR 45KW/119NM

UPGRADE TAPER TO HSK100A

60 TOOLS ATC MAGAZINE

X/Y-AXIS WITH LINEAR MOTOR DRIVE; Z-AXIS WITH BALL-SCREW DRIVE

X/Y/Z-AXIS WITH HIGH RIGIDITY ROLLER TYPE LINEAR GUIDE-WAY

COOLER FOR LINEAR MOTORS

GERMANY BRAKING SYSTEM FOR LINEAR MOTOR

5-AXIS WITH HEIDENHAIN OPTICAL LINEAR / CIRCULAR SCALE

AIR-CONDITIONER FOR ELECTRICAL CABINET

COUNTER BALANCE SYSTEM

WATER-PROOF WORKING LAMP

SPINDLE CHILLER

OIL-AIR LUBRICATION DEVICE FOR SPINDLE

COOLANT AROUND SPINDLE

OIL MIST AROUND SPINDLE

CHIP FLUSHING SYSTEM

STANDARD CHIP CONVEYOR SYSTEM

STANDARD WATER TANK

SECURITY DOOR INTERLOCKS

SPINDLE THERMAL COMPENSATION

AIR DRYER

AUTO ROOF

We use cookies to improve your experience. Privacy Policy.