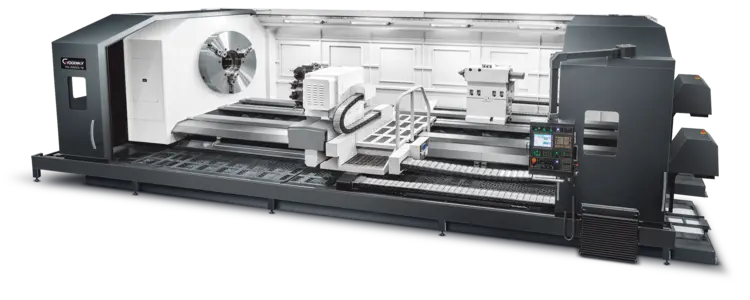

Together with the latest technology and high-quality components, the Goodway Flat-bed CNC Turning Center, HA series, utilizes high rigidity four box way bed with a 3-step gear spindle and servo indexing turret, to provide heavy-duty cutting capability for super large size workpiece applications. It is suitable for the oil and energy industry, aerospace and shipbuilding industry, and metallurgy industry. The optional four-way toolpost, boring tooling, and high rigidity steady rest equipment provide a more efficient turning performance for large workpiece applications. Furthermore, the live tooling center and C-axis are also available which allows the machine to perform more complicated tasks such as turning, milling, and drilling to fulfill your needs for today and tomorrow.

KEY FEATURES:

• One-piece 4-box way and flatbed casting provide a large platform with a heavy-duty structure, suitable for super large size workpiece applications.

• 3-step gear spindle provides great torque output under low speed, to fulfill heavy cutting needs.

• Key components such as the X-axis saddle, turret, and tailstock are designed with optimized configuration, to greatly increase structural rigidity and ensure both heavy-duty cutting and precision turning capabilities.

• Z-axis twin chip conveyor system with a separated large coolant tank design provides highly efficient chip disposal and stable turning accuracy.

We use cookies to improve your experience. Privacy Policy.