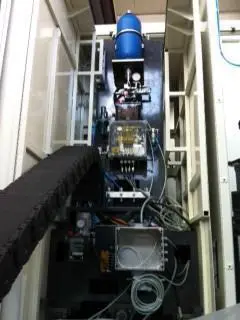

The machine design is based on a longitudinal traveling column with a central fixed rotary table. This design concept guarantees machine stability and accuracy for high milling performance. An effective chip removal and flush coolant system facilitates chip evacuation. The servo drives combined with ball screws and roller guides ensure high positioning accuracy and a high feed speed. Axis movement is measured by Heidenhain absolute optical scales. The type of spindle allows machining different types of material, including light metal alloys or very hard steel alloys.

KEY FEATURES:

• High power output

• High precision

• High stability

• Large working area High speed

• Simple and effective chip removal system to keep the working area clean

• High-performance control system

• Easy access to the working area

X-AXIS = 3200 MM

Y-AXIS = 1200 MM

Z-AXIS = 1500

A-AXIS (HEAD) = ± 120°

ELECTRO-SPINDLE HSK 100A

HIGH PRESSURE THROUGH THE SPINDLE 40 BAR

HEIDENHAIN NUMERICAL CONTROL, MODEL TNC 530 15” TFT COLOUR

TOOL CHANGE WITH 30 + 30 RANDOM

HEIDENHAIN ABSOLUTE OPTICAL SCALES

ROTARY TABLE 1200 MM X 1200 MM

MOVABLE CONSOLE FOR THE ENTIRE WORKING AREA

COOLER FOR HEAD, TABLE AND ELECTRO-SPINDLE

ELECTRIC CABINET CONDITIONER

LUBRICATION FOR MOVING DEVICES

WORKING AREA INTEGRAL FAIRING

COVER FOR MOVING PARTS

CHIP EVACUATOR WITH GOOSE-NECK OUTLET

We use cookies to improve your experience. Privacy Policy.