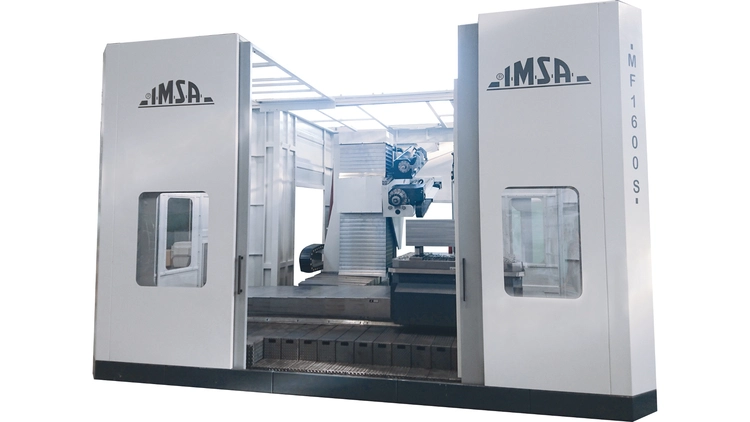

IMSA MF1600/S2 - Gun Drilling and Milling Machine

The IMSA MF1600/S2 is a versatile gun drilling and milling center specifically designed for the mold-making industry, catering to manufacturers of tools and dies weighing up to 30 tons. With its T-shaped structure, heavy-duty build, and advanced features, this machine ensures precision and efficiency in handling complex and large-scale workpieces. Designed for tool and die manufacturers, the IMSA MF1600/S2 delivers outstanding versatility, enabling milling, gun drilling, and 5-axis machining in one compact setup. Its robust construction, advanced features, and precision make it the perfect choice for large-scale, high-complexity production.

Key Features:

High-Performance Structure:

• Heavy-duty electrowelded design for maximum stability.

• Accommodates molds up to 3600 mm in diameter.

• T-shape design: Translating table (X-axis: 3000 mm) and transversal movable column.

4-Side Machining Capability:

• Rotating Table (B-axis): Infinite-position rotation for orthogonal, single-angle, and compound-angle machining.

• Long transversal movement allows full 4-side machining in a single setup.

Dual Machining Units:

• Milling Unit:

- ISO50 spindle, 35 kW, 6,000 rpm, 334 Nm, liquid-cooled motor.

- Optional ISO50 tool storages for expanded capacity.

• Gun Drilling Unit:

- Drilling depth: Up to 1600 mm.

- Optimal diameter range: 5-32 mm (up to 40 mm).

- Gun drill spindle: 15 kW, 4,200 rpm.

We use cookies to improve your experience. Privacy Policy.