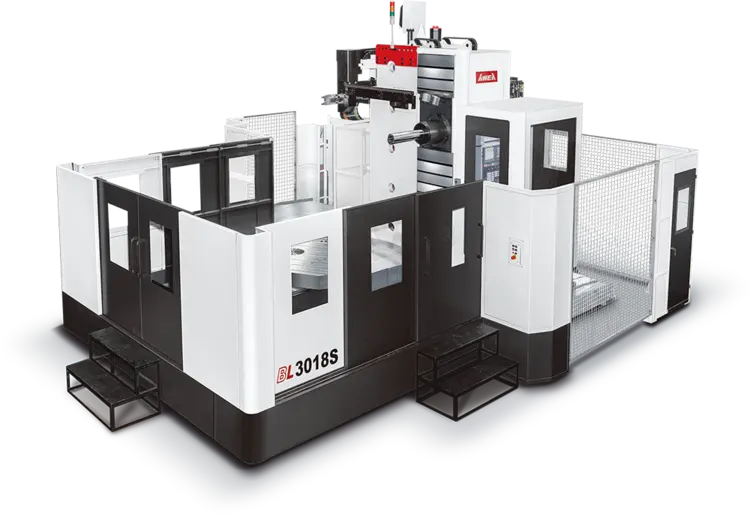

Introducing AWEA with mature manufacturing abilities and advanced technology skills. The BL series combines a high rigidity structure, heavy-duty load capacity rotary table, and a high torque spindle ( BL-S ) along with our professional assembly and hand scraping skills. BL series can easily overcome the most stringent requirements of not only deep hole boring but high precision mold milling which meet your various needs for today and the future.

Key Highlights:

• Modular spindle design, BL-S quill type 2-step gearbox spindle continuous torque can be from 1,308 N-m; BL-FM ram type built-in spindle speed up to 8,000 rpm

• High damping, low friction oil floating design working table provides maximum table load capacity at 15,000 kg ( Opt. )

• Balanced arrangement of tool magazine and headstock on the column to ensure excellent positioning accuracy

• Horizontal boring mills provide better chip removal ability

FANUC 0I-MF CONTROL WITH10.4” LCD DISPLAY

ICONSOLE WITH OPTIMIZED PARAMETER, AFC

W AXIS UPGRADED TO 900 MM, QUILL Ø 130 MM

2,400 RPM GEAR DRIVEN SPINDLE, 22 / 26 KW, CAT50 BIG PLUS

40 TOOLS CAPACITY MAGAZINE

35 BAR COOLANT THROUGH SPINDLE SYSTEM, ALLCOOL MB500, WITHOUT CTS TANK, MANUAL PRESSURE ADJ., SINGLE FILTER (WITH SUB TANK)(HOSES AND ROTARY JOINT 1000PSI CAPABLE)

LINEAR SCALE ON X/ Y/ Z AXIS

OIL LUBRICANT SEPARATOR

CATERPILLAR TYPE CHIP CONVEYOR AND CHIP BUCKET

CATERPILLAR TYPE CHIP CONVEYOR WITH 1,200MM DISCHARGE HIGH

FULL ENCLOSED SPLASH GUARD (WITHOUT ROOF ENCLOSURE)

SPINDLE COOLING SYSTEM

COOLANT SYSTEM WITH PUMP AND TANK

CENTRALIZED AUTOMATIC LUBRICATING SYSTEM

LUBRICANT RECYCLING COLLECTOR

MOVABLE OPERATION CABINET AND STAIRS

0.001° INDEXING ROTARY TABLE

HEAT EXCHANGER FOR ELECTRICAL CABINET

WATER GUN AND AIR GUN

ALARM LIGHT

We use cookies to improve your experience. Privacy Policy.