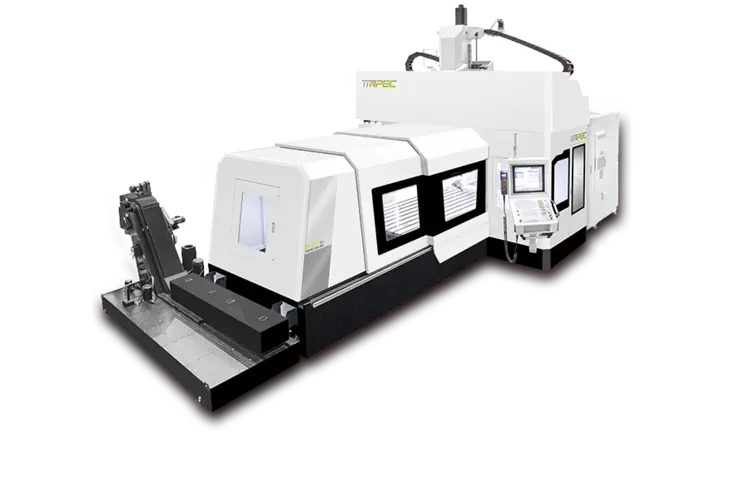

The APEC MT-1520 is a precision-engineered 5-axis high-speed gantry machining center built for high-performance mold machining, aerospace components, and complex part manufacturing. Designed with a rigid double-column gantry structure and advanced thermal stability, the MT-1520 delivers exceptional accuracy, dynamic performance, and reliable multi-axis control.

This powerful machine is equipped with a 15,000 RPM HSK-A100 built-in spindle, providing 45/54 kW (S1/max) power and up to 143 Nm of torque—ideal for high-speed, high-precision cutting of hardened materials and intricate mold surfaces. The 2-axis fork-type milling head enables full 5-axis simultaneous machining, with ±115° B-axis and ±360° C-axis rotation, driven by direct-drive motors for enhanced speed and positioning accuracy.

With travels of X: 2,000 mm, Y: 1,500 mm, and Z: 900 mm, and an optional 1,200 mm Z-axis upgrade, the MT-1520 provides ample working space for medium-to-large parts. The high-speed linear motors on the X and Y axes, roller-type guideways, and robust Heidenhain TNC640 CNC control system ensure smooth, accurate, and fast operation.

Key Features:

• 2-axis direct-drive fork-type milling head (±115° B / ±360° C)

• Heidenhain TNC640 5-axis controller with HR520 manual pulse generator

• X/Y axis linear motors for backlash-free high-speed movement

• Positioning accuracy: ±0.010 mm; repeatability: ±0.005 mm

• Optional BLUM probe, laser tool measurement, 70 bar CTS, and chip conveyor

Whether you're machining precision molds, structural aerospace parts, or complex 5-axis geometries, the APEC MT-1520 Gantry Machining Center delivers the speed, precision, and flexibility to meet today’s demanding manufacturing standards.

HEIDENHAIN TNC640 5-AXIS CNC CONTROLLER WITH HR510 MPG

AGA MONO TYPE 2-AXIS MILLING HEAD

24,000 RPM BUILT-IN SPINDLE, 35 / 42 KW (S1/S6), 56 / 67 NM(S1/S6), HSK63A

32 TOOLS ATC MAGAZINE

X/Y/Z-AXIS WITH HIGH-SPEED BALL-SCREW DRIVE

X/Y/Z-AXIS WITH HIGH RIGIDITY ROLLER TYPE LINEAR GUIDE-WAY

X/Y/Z/A/C-AXIS WITH HEIDENHAIN LINEAR/ CIRCULAR OPTICAL SCALE

70 BAR COOLANT THROUGH SPINDLE SYSTEM WITH AIR THROUGH THE SPINDLE

BLUM WORK PIECE TOUCH PROBE

BLUM TOOL MEASURING SYSTEM

AUTOMATIC KINEMATICS MEASUREMENT & CALIBRATION SYSTEM WITH CERAMIC BALL SET

AIR-CONDITIONER FOR ELECTRICAL CABINET

SPINDLE CHILLER

OIL-AIR LUBRICATION DEVICE FOR SPINDLE

COOLANT AROUND SPINDLE

OIL MIST AROUND SPINDLE

CHIP AUGER SYSTEM

STANDARD COOLANT TANK

SAFETY INTERLOCK OF FRONT AND BACK DOOR

FULLY ENCLOSURE SPLASH GUARD

SPINDLE THERMAL COMPENSATION

WATER-PROOF WORKING LAMP

AIR DRYER

We use cookies to improve your experience. Privacy Policy.