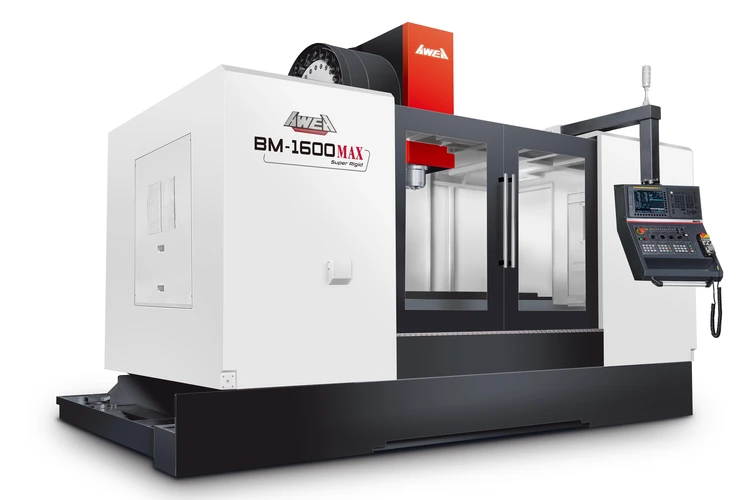

AWEA BM-1800 MAX – Heavy-Duty 3-Axis Vertical Machining Center for Superior Cutting Power and Rigidity

The AWEA BM-1800 MAX is a high-performance 3-axis vertical machining center built for heavy-duty cutting, rigid stability, and long-term precision. Designed with a powerful gear-driven CAT50 spindle, hardened and ground box ways on all three axes, and precision hand-scraped contact surfaces, this machine delivers exceptional results in demanding milling environments such as aerospace, energy, defense, and precision general engineering.

Featuring an X-axis travel of 1800 mm, Y and Z axes of 800 mm, and a large 2000 × 800 mm table supporting up to 2,200 kg, the BM-1800 MAX provides ample workspace for large and heavy components. The machine is built on a robust cast iron structure enhanced with Δ (Delta) wide-span column design and BESSEL POINTS concept for optimized saddle support—minimizing deformation while maximizing table accuracy and cutting stability.

The gearbox spindle system offers 6,000 RPM with high torque (up to 60 HP peak) via a FANUC Alpha 22i motor, delivering outstanding metal removal rates with consistent performance. AWEA’s in-house designed gear mechanism ensures reliability and durability with automatic lubrication and cooling for extended service life. Equipped with FANUC 0i-MF Plus CNC, conversational programming, and advanced look-ahead functions, the BM-1800 MAX is engineered to maintain speed, precision, and repeatability in every cycle.

From high-speed rigid tapping to the programmable coolant chip flush system, and from dual internal chip augers to a full-enclosure splash guard, every aspect of this machine is optimized for performance, longevity, and ease of use. With a comprehensive set of built-in and optional features, the BM-1800 MAX stands as a reliable, production-ready solution for heavy machining applications.

FANUC 0i-MF PLUS WITH 10.4” LCD SCREEN

MANUAL GUIDE i + i CONSOLE

SUB PANEL FOR ATC

UPGRADED WITH AICCII + DATA SERVER PRE-READ 400 BLOCKS

6 000 RPM, GEAR BOX, CAT 50 BIG PLUS

UPGRADED TO 60 HP/PEAK SPINDLE MOTOR

UPGRADED TO 40 TOOLS ATC MAGAZINE CHAIN TYPE

RENISHAW OMP60 + OTS WIRELESS AND PROBING SYSTEM

RENISHAW GRAPHIC USER INTERFACE

UPGRADED TO CTS 500 PSI

AIR THROUGH SPINDLE

ROLLER TYPE

UPGRADED TO SECURE FRONT WINDOW

COMPACT FLASH CARD 32GB - A02B-0213-K217

CONVEYOR

4TH AXIS READY

3 AXIS AUTO LUBRICATION SYSTEM

3 AXES BALL SCREW PRETENSION

SPINDLE AIR CURTAIN

SPINDLE OIL CHILLER

COOLANT NOZZLES AROUND SPINDLE

ROOF ENCLOSED SPLASH GUARD

AIR BLOW SYSTEM

RIGID TAPPING

CENTRALIZED AUTOMATIC LUBRICATION ( X / Y / Z )

AIR TANK FOR TOOL MAGAZINE

LUBRICANT RECOVERING SYSTEM

OIL SKIMMER

HEAT EXCHANGER FOR ELECTRIC CABINET

RJ-45 ETHERNET INTERFACE

RS-232 INTERFACE

COOLANT EQUIPMENT

AIR GUN

COOLANT GUN

ALARM LIGHT & WORK LIGHT

ADD (2) TWO FLUORESCENT LIGHTS

AUTOMATIC POWER-OFF SYSTEM

TOOLBOX

FOUNDATION BOLT KIT

We use cookies to improve your experience. Privacy Policy.