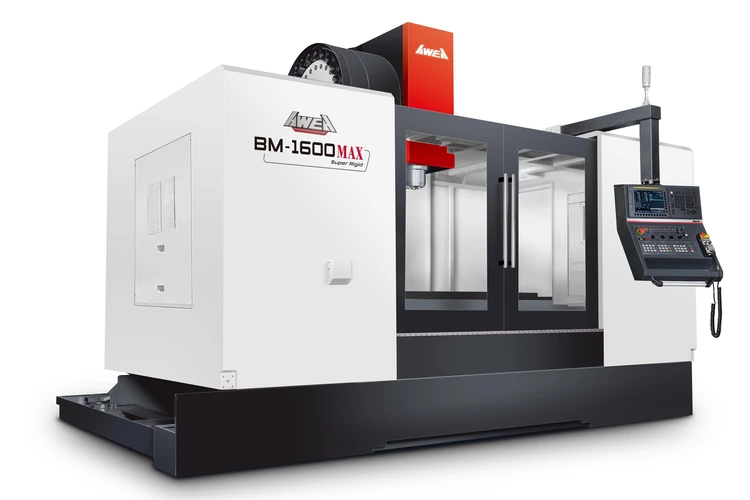

AWEA BM-1600 MAX – Precision Vertical Machining Center for Heavy-Duty Applications

The AWEA BM-1600 MAX is a high-rigidity vertical machining center built to meet the demands of heavy-duty and high-precision machining. Engineered with a durable C-frame structure, it delivers outstanding stability and cutting performance—making it a trusted solution for industries such as mold and die, aerospace, and general part manufacturing. Designed for flexibility, the BM-1600 MAX supports a range of spindle configurations, tool changers, and control options, allowing it to be tailored to your production needs. Whether you're in Ontario, Montreal, Windsor, Quebec, or anywhere across Canada or the USA, this machine delivers consistent accuracy, speed, and reliability for complex machining operations.

Ideal for Multiple Industries: Optimized for mold machining, aerospace components, and precision engineering.

Key Features:

• Generous Travel Range: X: 1,600 mm / Y: 800 mm / Z: 800 mm – ideal for medium to large workpieces

• Heavy-Duty Table: 1,700 mm × 800 mm working area with up to 2,000 kg table load capacity

• Flexible Spindle Options: Available with various spindle speeds and motor outputs, including high-torque and high-speed configurations (e.g., up to 6,000 RPM or more, BT50 taper)

• Customizable Tool Changer: ATC capacity starts at 24 tools and can be configured up to 60 tools, depending on application requirements

• Fast and Accurate Movement: High-speed axis movement with robust guideways for smooth machining and reduced cycle time

• Advanced CNC Control: Equipped with FANUC or Mitsubishi control options for intuitive operation and high precision

• Stable C-Frame Design: Ensures excellent rigidity, thermal stability, and long-term accuracy during extended machining

FANUC 0I-MF PLUS WITH 15" LCD SCREEN

AICC II (400 BLOCKS) + 2GB DATA SERVER

UPGRADED TO 8,000 RPM GEAR DRIVEN SPINDLE, CAT50 BIG PLUS

UPGRADED TO 60 TOOLS ATC MAGAZINE

BOX WAY

70 BAR COOLANT THROUGH SPINDLE, ALLCOOL MB300, WITHOUT CTS TANK, MANUAL PRESSURE ADJ., SINGLE FILTER (HOSES AND ROTARY JOINT 1000PSI CAPABLE)

AIR THROUGH SPINDLE

ELECTRICAL CABINET HEAT EXCHANGER

CHIP WASH DOWN COOLANT

CATERPILLAR-TYPE CHIP CONVEYOR

CENTRALIZED AUTOMATIC LUBRICATING

SPINDLE AIR CURTAIN

OIL LUBRICANT SEPARATOR (OIL SKIMMER)

AUTOMATIC POWER-OFF SYSTEM

AIR TANK FOR TOOL MAGAZINE

SIDE DOOR WITH WINDOW ON THE LEFT AND RIGHT OF MACHINE

DOOR INTERLOCK

ROOF ENCLOSURE SPLASH GUARD

We use cookies to improve your experience. Privacy Policy.