* SEND US YOUR OFFER PRICE *

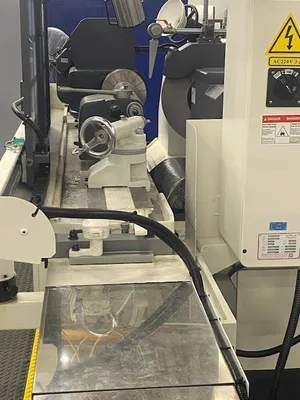

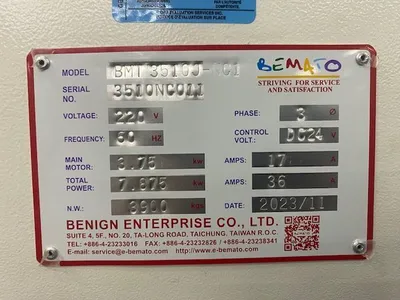

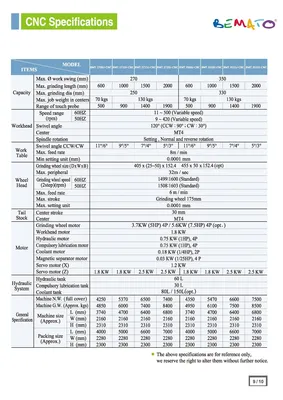

The BEMATO BMT-3510J NC1 is a high-performance NC universal cylindrical grinder designed for precision grinding of shafts, rods, and similar workpieces. With a maximum swing over work of 350 mm and a maximum grinding length of 1000 mm, it accommodates a maximum grinding diameter of 330 mm and supports up to 130 kg workpieces in centers (for the 3510 series). According to published BEMATO CNC specifications, its workhead offers a variable speed range (60 Hz) of 11 to 500 rpm, while at 50 Hz it operates from 9 to 420 rpm. The workhead is mounted on an MT4 taper and offers a swivel range of ± (CCW 90° : CW 30°) for angular grinding. (From your spec sheet: swivel angle = 120° total, CCW 90°, CW 30°.)

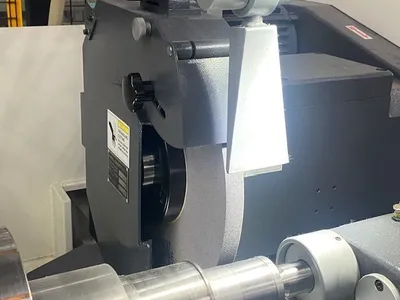

The machine’s table travel is finely controllable, with a maximum feed rate of 8 m/min and a minimum incremental feed (setting unit) of 0.0001 mm. The grinding wheel head can accommodate wheels sized 455 × 50 × 152.4 mm (optionally), and the standard wheel head configuration runs a two-step speed of 1499 / 1600 rpm (60 Hz) or 1508 / 1603 rpm (50 Hz). Its maximum peripheral speed is rated at 32 m/sec. Table swivel angles differ slightly depending on model variant (e.g. 11°/6°, 9°/5°, 7°/4°, 5°/3°) depending on which BMT-35xxJ model is used (the “10” variant uses 9°/5° for example). The wheel head’s maximum feed rate is 6 m/min, and the stroke (grinding wheel cross travel) is 175 mm.

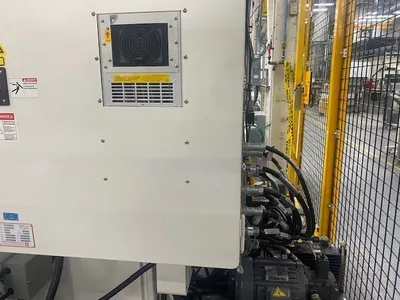

In terms of power and drive, the grinding wheel motor is rated at 3.7 kW (5 HP) with an optional upgrade to 5.6 kW (7.5 HP). The workhead motor is 1.8 kW, while the tailstock (center stroke 30 mm, center taper MT4) is provided for support during through-grinding operations. The hydraulic system includes a 60 L main hydraulic tank and a 30 L compulsory lubrication tank; coolant capacity is standard at 80 L, with an optional 150 L capacity for heavy duty use. The machine is fully enclosed (full cover), and in its fully enclosed specification its footprint measures approximately 4350 mm (L) × 2160 mm (W) × 2310 mm (H) with a gross weight of 4950 kg (machine weight ~ 4350 kg). (These dimensions come from the general spec row in your document.)

Beyond these base parameters, BEMATO incorporates precision engineering features to ensure long-term stability and accuracy. According to BEMATO’s technical documentation, the X and Z axes slideways are coated with Turcite-B, providing low friction, reduced wear, and sustained positional accuracy over time.

tmts.tw

The machine's bed and structure are cast, stress-relieved, and rib-reinforced to maintain rigidity under load. The workhead spindle is expected to be precision ground, normalized, and supported in a robust bearing arrangement, though BEMATO does not explicitly state hydrostatic bearings for this model (unlike some high-end CNC cylindrical grinders).

In practical operation, the BMT-3510J NC1 is ideal for precision grinding of cylindrical workpieces in tool shops, mold shops, aerospace, automotive component finishing, and general job shop environments. Its swivel workhead allows for taper and angular surface grinding in addition to straight plunge grinding. The fine feed resolution of 0.0001 mm enables ultra-precise finishing, and the variable speed workhead ensures compatibility with a wide range of workpiece materials and surface finish demands. Optionally, the machine can be equipped with wheel dressers, work probes, automatic balancing, and coolant filtering systems to enhance automation, reduce downtime, and improve consistency.

In sum, the BEMATO BMT-3510J NC1 offers a well-balanced combination of capacity, precision, versatility, and robust design — well suited for shops that require reliable, high-accuracy cylindrical grinding with angular capability.

We use cookies to improve your experience. Privacy Policy.