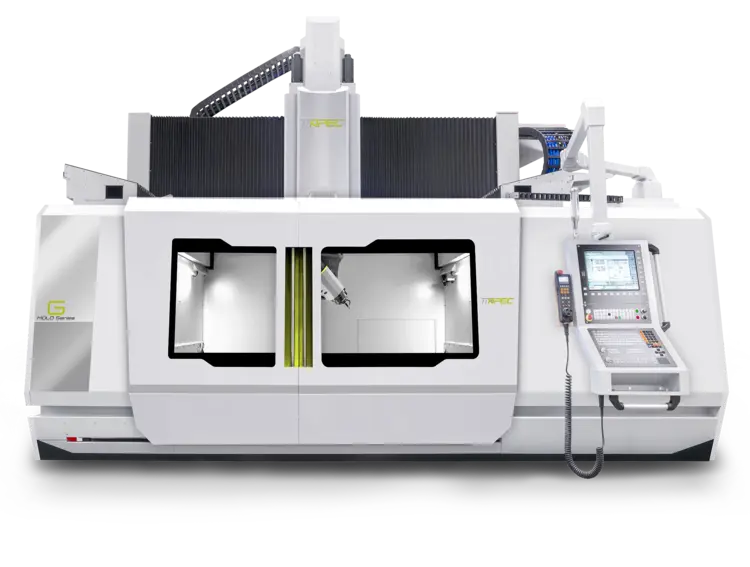

The APEC G3060 is a high-performance 5-axis high-speed gantry machining center engineered for precision machining of large, complex components in aerospace, automotive, mold & die, and aluminum structural applications. Featuring a rigid gantry-type structure with a fixed table design, the G3060 delivers exceptional stability, vibration damping, and consistent machining accuracy even under heavy cutting loads. With expansive travels of 6,000 mm (X) × 3,000 mm (Y) × 1,000 mm (Z)—upgradeable to 1,200 mm Z-axis—this machine is optimized for large-format workpieces while maintaining high dynamic performance

Powered by a 15,000 RPM HSK100A built-in spindle delivering up to 45 kW (S1) / 54 kW (S6) and 143 Nm of torque, the APEC G3060 is designed for both high-speed finishing and heavy material removal. The standard Mono-type 5-axis milling head provides ±125° swivel on the A-axis and full 360° rotation on the C-axis, enabling true simultaneous 5-axis machining and undercut operations, while an optional Fork-type milling head expands angular flexibility for complex geometries. High clamping torque on rotary axes ensures rigidity and surface accuracy during demanding machining cycles

Precision motion control is achieved through linear motor drives on the X and Y axes, eliminating backlash and wear while enabling rapid traverse rates up to 60 m/min, complemented by a high-precision ball screw-driven Z-axis with speeds up to 40 m/min. Integrated Heidenhain optical linear and rotary scales across all axes support exceptional positioning accuracy and repeatability, with 5-axis TCPM accuracy rated at ±0.03 mm, making the G3060 ideal for high-tolerance production environments

The machine is equipped with a Heidenhain TNC7 5-axis CNC controller, offering advanced tool center point management (TCPM), high-speed look-ahead processing, smooth path interpolation, and full 5-axis kinematic compensation. Standard features include an HSK100A automatic tool changer (20-tool capacity, expandable to 40 tools), spindle thermal compensation, air and coolant systems around the spindle, and a fully enclosed workspace with chip conveyor for clean and efficient operation. Optional BLUM probing and laser tool measurement systems further enhance automation, accuracy, and unmanned machining capability

Designed for manufacturers demanding precision, rigidity, and scalability, the APEC G3060 5-Axis Gantry Machining Center combines advanced motion technology, powerful spindle performance, and large working capacity into a single platform optimized for high-value, multi-axis machining applications.

HEIDENHAIN TNC7 5-AXIS CNC CONTROLLER WITH HR520 MPG

AGA MONO TYPE MILLING HEAD

15,000 RPM BUILT IN SPINDLE , 45 / 54 KW (S1/S6), 119 / 143 NM(S1/S6), HSKA100

40 TOOLS ATC MAGAZINE

OIL AIR LUBRICATION DEVICE FOR SPINDLE

X/Y AXIS WITH LINEAR MOTOR DRIVE

CHILLER FOR LINEAR MOTORS

GERMANY BRAKING SYSTEM FOR LINEAR MOTOR

Z-AXIS WITH HIGH-SPEED BALL SCREW DRIVE

X/Y/Z AXIS WITH HIGH RIGIDITY ROLLER TYPE LINEAR GUIDE WAY

5-AXIS WITH HEIDENHAIN OPTICAL LINEAR / CIRCULAR SCALE

COUNTERBALANCE SYSTEM

CHIP AUGER SYSTEM (INCLUDING CHIP CONVEYOR)

STANDARD COOLANT TANK

SPINDLE CHILLER

SPINDLE THERMAL COMPENSATION

AIR THROUGH SPINDLE

AIR AROUND SPINDLE

OIL MIST AROUND SPINDLE

COOLANT AROUND SPINDLE

AIR CONDITIONER FOR ELECTRICAL CABINET

AIR DRYER

WATERPROOF LED WORKING LAMP

SAFETY INTERLOCK OF FRONT AND BACK DOOR

We use cookies to improve your experience. Privacy Policy.