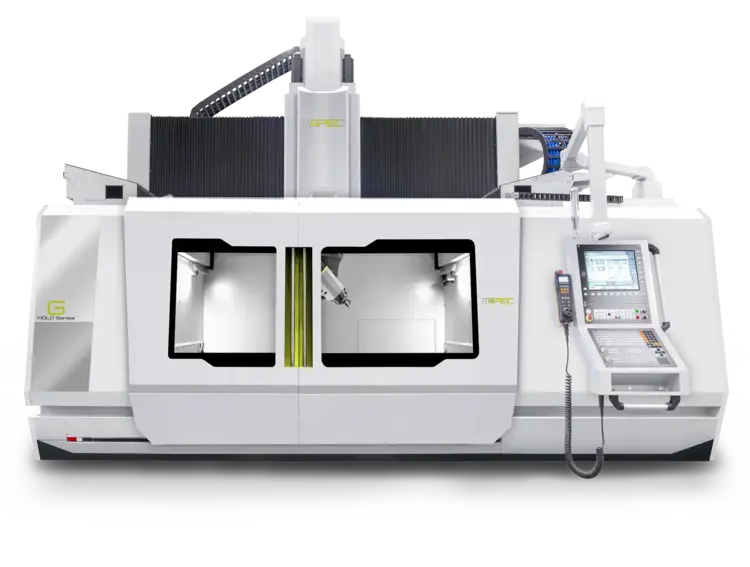

The APEC SK2540-5L 5-Axis High Speed Gantry Machining Center is designed for manufacturers who demand precision, rigidity, and speed in large-scale machining. Built with a double-column gantry structure and advanced 5-axis simultaneous machining capability, the SK2540-5L ensures exceptional stability and accuracy for complex geometries and multi-surface machining.

With a spindle speed of up to 24,000 RPM, linear motor-driven axes, and high-performance rotary tables, this machine is optimized for the aerospace, automotive, energy, and mold-making industries. Its oversized working envelope and high-load table capacity allow it to handle large, heavy workpieces while maintaining excellent dynamic accuracy. The gantry design minimizes vibration and ensures consistent precision, even under high-speed and heavy-duty cutting conditions.

The SK2540-5L is equipped with advanced automation features including an automatic tool changer (ATC), high-pressure through-spindle coolant system, and centralized lubrication, reducing downtime and maximizing productivity. With Siemens or Fanuc CNC controls available, operators benefit from intuitive programming, real-time monitoring, and high-speed processing.

This machining center provides a perfect balance of power, speed, and precision, making it a trusted solution for industries requiring superior surface finishes, tight tolerances, and maximum efficiency.

Key Features

• 5-Axis High Speed Gantry Machining for multi-surface precision and efficiency

• Spindle up to 24,000 RPM with high-torque capability

• Large working envelope designed for oversized and heavy workpieces

• Double-column gantry structure for maximum rigidity and vibration reduction

• Linear motor-driven axes for high speed and accuracy

• Automatic tool changer (ATC) for uninterrupted production

• High-pressure through-spindle coolant system for efficient chip removal and tool life extension

• Centralized lubrication system for low-maintenance operation

• Compatible with Siemens or Fanuc CNC controls with advanced programming and monitoring features

• Ideal for aerospace, automotive, mold, energy, and heavy machinery applications

HEIDENHAIN TNC640 5-AXIS CNC CONTROLLER WITH HR520 MPG

AGA MONO TYPE MILLING HEAD

24,000 RPM BUILT-IN DRIVEN SPINDLE, HSK63A

SPINDLE MOTOR 60 / 75 KW, SPINDLE TORQUE 48 / 60 NM

30 TOOLS ATC MAGAZINE

X/Y-AXIS WITH LINEAR MOTOR DRIVE

Z-AXIS WITH DOUBLE BALL SCREW DIVE

X/Y/Z-AXIS WITH HIGH RIGIDITY ROLLER TYPE LINEAR GUIDE-WAY

COOLER FOR LINEAR MOTORS OF X/Y-AXIS

GERMANY BRAKING SYSTEM FOR LINEAR MOTOR

5-AXIS WITH HEIDENHAIN OPTICAL LINEAR / CIRCULAR SCALE

AIR-CONDITIONER FOR ELECTRICAL CABINET

SPINDLE CHILLER

OIL-AIR LUBRICATION DEVICE FOR SPINDLE

COOLANT AROUND SPINDLE

CHIP FLUSHING SYSTEM

ENLARGE COOLANT TANK

SECURITY DOOR INTERLOCKS

COUNTER BALANCE SYSTEM

WATER-PROOF WORKING LAMP

AIR DRYER

We use cookies to improve your experience. Privacy Policy.